Winch assist machines are improving logger safety on some of the toughest sites to log. They serve as an anchor for heavy equipment, making it possible to log many steep slopes from the safety of a cab rather than having to cut trees on foot. In this story, we show how a winch-assist system works.

FORKS, Washington—After more than 40 years of using chainsaws to cut trees on steep slopes, Dave Dilley remembers the first time he watched a winch-assist machine in action.

He stood in the forest, unable to take his eyes off a feller buncher as it eased up and down the mountain. Without the winch-assist machine, the buncher—a machine that efficiently cuts down trees and “bunches” them together—would be at risk of toppling, sliding or at least digging deep ruts into the soil.

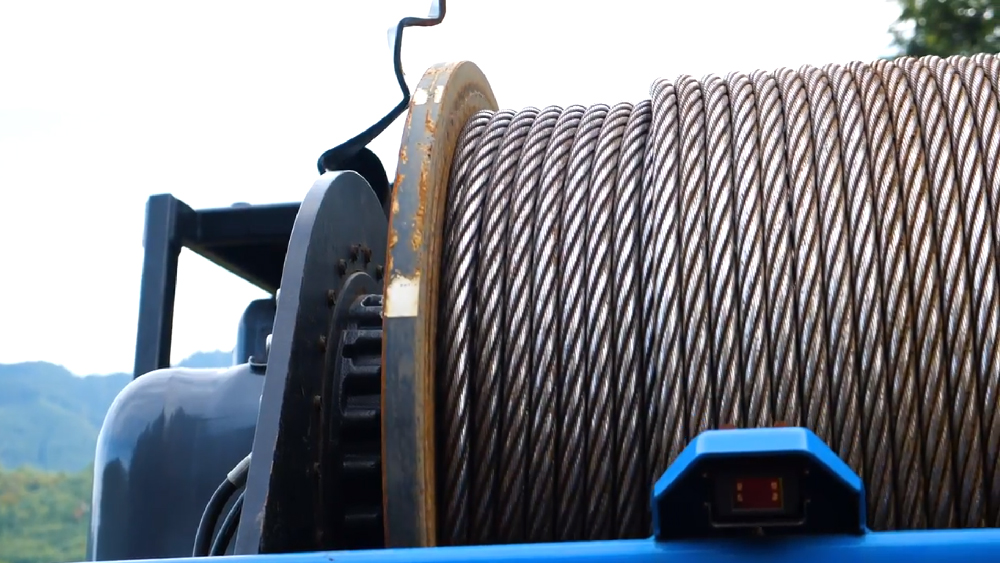

But the winch, a machine that anchors into place and supports the buncher with a powerful cable, enabled the buncher operator to move across the terrain easily, using a simple device to operate the winch-assist machine from within the cab of the buncher.

“I just saw where it would work here,” says Dave, owner of Dilley & Soloman Logging Company and a lifelong resident of this small town on the Olympic Peninsula in northwest Washington. It wasn’t long before Dave had two winch assist machines of his own.

The Logging System is Safer for Loggers

“The most important thing with this procedure is safety. It’s always our first concern,” says Rayonier Timber Production Forester Dennis Cox, who encouraged Dave to make the change.

The logger agrees.

“You need less people on the ground, so there’s less danger. That’s the big reason we got into this type of logging,” he says.

Slopes that are too steep for a buncher have to be cut on foot. Loggers walk down the steep terrain and cut trees by hand with chainsaws. It’s one of the most dangerous jobs in the industry.

There are still some slopes that are too steep to operate a buncher on, even with a winch-assist machine, but the machine has enabled many sites to be logged in a safer, more efficient and eco-friendly manner than ever before.

Helps Lighten Environmental Impact

“Logging operations on any slope steeper than 30 percent need some form of support,” says Rayonier’s Senior Timber Marketing Manager Dan Stransky. That guideline, set by the Department of Natural Resources, helps ensure a harvest that’s safe for workers and the environment.

“They don’t want us putting big ruts up and down the hillside because, when the rains come later, all that water runs down those gullies and it delivers sediment to those streams,” he explains, “so it’s just something we work hard at avoiding.”

Seeing the Environmental Benefits of Using the Winch Assist Machine

Dave says the winch assist machine allows him to do his work with a lighter impact on the soils.

“There are certain spots where you have to be pulled” by the winch-assist machine, he says. “There are others I could probably log unassisted, but I’d be turning up my tracks and making ruts.

“If I just push [the winch assist controls] to, say, a four, it just pulls me right up and doesn’t create any tracks.”

Up against the heavy rains this region is known for, the winch-assisted logging system is one of many ways Rayonier works with contractors to keep sediment from reaching waterways.

Why? Sediment would interfere with precious habitats in and around the water. It would also be harmful to our work, washing away the rich soils we’ve developed over decades of forestry. As we explain in the article Forest Engineers Build 100s of Eco-Friendly Roads and Bridges, we adjust all projects and operations to have the lightest possible impact on the environment.

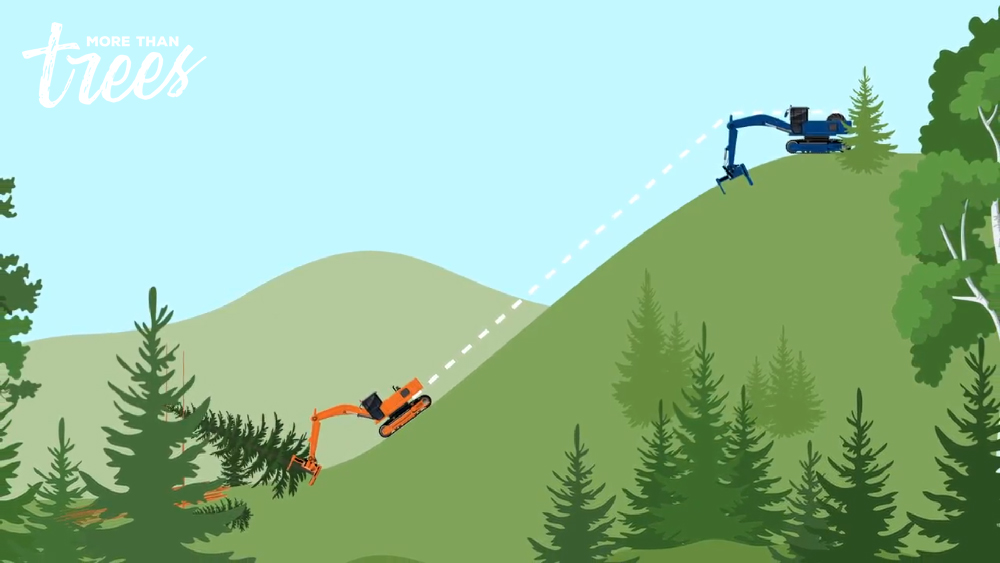

How a Winch Assist Logging System Works

So how does a winch assist logging system keep a feller buncher from slipping on a steep slope? The base machine anchors into place on flat ground above the slope.

Dave explains: “You just dig, point the bucket all the way forward, and get it down.”

He double-checks that it’s secure by ensuring the boom doesn’t move. Then he connects the cable from the winch to his buncher and gets to work, using a remote to control the strength of the winch’s pull on the buncher.

As an extra security measure, if the winch assist base machine moves at any point after it is set, an anchor switch immediately sounds a blaring alarm and applies brakes to the winch drums.

Dave says the trickiest part is the logistics of figuring out how best to position it on each site, “but the machine itself is very user-friendly.”

An Organized Harvest

At ground-level, the results of a harvest operation may look messy. But the view from above shows how carefully-planned each step of the harvest is. The trees lay in neat, straight rows.

“When we log with this system, we get a lot less breakage. It’s very organized,” says Dennis, Rayonier Timber Production Forester. “With a drone, when you look down on it, it should look like combed hair. And it does.”

After cutting finishes, a second operation involving a cable yarding system, also known as tower logging, is used to bring trees up the slope (again without damaging the soiles). At the top of the landing, they’re sorted and loaded onto trucks.

Harvesting in a Responsible Way

Dave has been in the logging industry for four decades, starting out with his uncle when he was a young man. He’s seen a number of changes over the years, and he’s proud of the strides the industry has made to protect loggers’ safety—as well as the environment.

Despite the stereotype that loggers “pillage” the land, he says, “we may be the best environmentalists out there. Yes, we do want to harvest, but we want to do it in a responsible way. We’re very conscious of streams and wildlife.”

Leave a Comment