What is tower logging and how does it work? In this article, we help you understand how this steep slope logging technique works.

GRAYS RIVER, Washington—Have you ever wondered how terrain that’s hard to even walk on could be used in forestry operations?

A technique that has vastly improved logger safety—and prevents erosion and sedimentation into waterways—uses a cable system to hoist logs high into the air to move them to flatter ground.

This popular method for moving logs off steep slopes has many names: tower logging, skyline logging, cable logging and cable yarding are among the most-used.

This overview will help you understand how we use this type of logging in the Pacific Northwest:

Beginning with An Organized Cutting Operation

Before a tower is even brought to the site, a logging crew will begin by cutting the trees and placing them on the ground in a neat, organized layout that will make them easier to move when the time comes.

While some slopes have to be logged on foot with chainsaws, many steep slope logging jobs are now being done with a winch assist system, which anchors into flat ground above and supports vehicles on the slope with a cable. The driver of a machine that cuts the trees on the slope uses a remote to control how strongly the winch assist system supports his vehicle.

Further Reading: You can learn more about winch-assisted logging and see a video of it in action in our story, Winch-Assisted Logging Boosts Safety on Steep Terrain.

Setting Up the Tower and Skyline

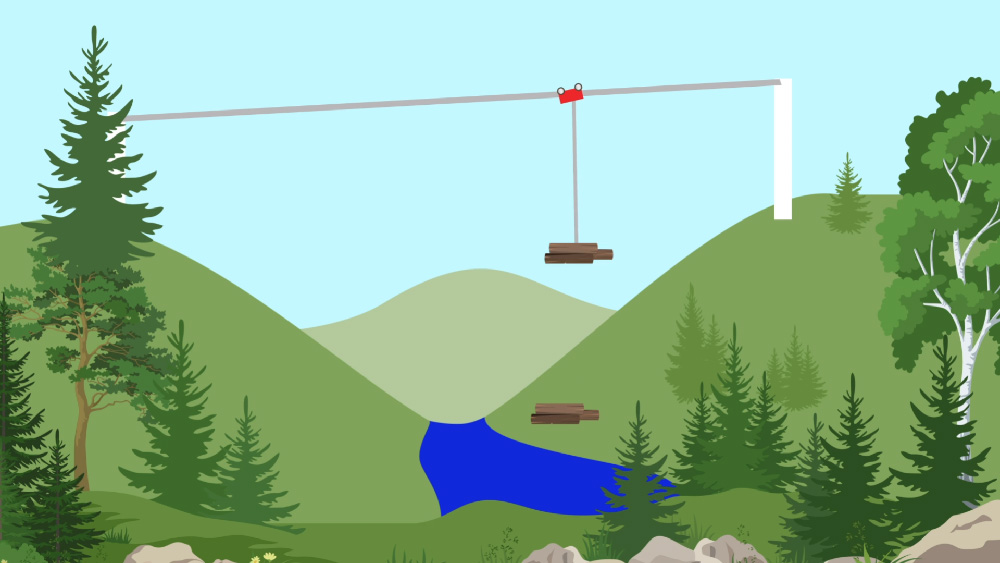

Once the trees are cut, it’s time to get them off the steep slope and onto a flat “yarding area” above the slope. In order to safely move them without damaging the ground, causing erosion or damaging the logs, we lift the logs high into the air.

To set the system up, first a large tower is put into place with the support of several cables called “guylines.” They connect to the tower and then anchor into place in various directions to ensure the tower remains steady against the weight of the logs.

The part of the tower that gives it height, referred to as a “tube,” can be 100 or more feet tall. Years ago, loggers used strong trees to serve as towers. But using man made, movable towers gives loggers a much more reliable option, with the added safety benefit of not having to climb a tree with heavy rigging.

Replacing Synthetic Haywire with Skyline Cable

Once the tower is anchored, it’s time to put the skyline cable in place. The strong cable, typically 1.25” thick, would be too heavy to carry across mountains. Instead, a lighter, synthetic cable called haywire or strawline is used first.

Getting this line into place can be dangerous: imagine how hard it is to walk up or down a mountainside, and now imagine doing it while carrying and unwinding 50 to 80 pounds of cable. The cable is usually 250 feet long, meaning it will take several trips to gather more cable to cover the thousands of feet between the slopes.

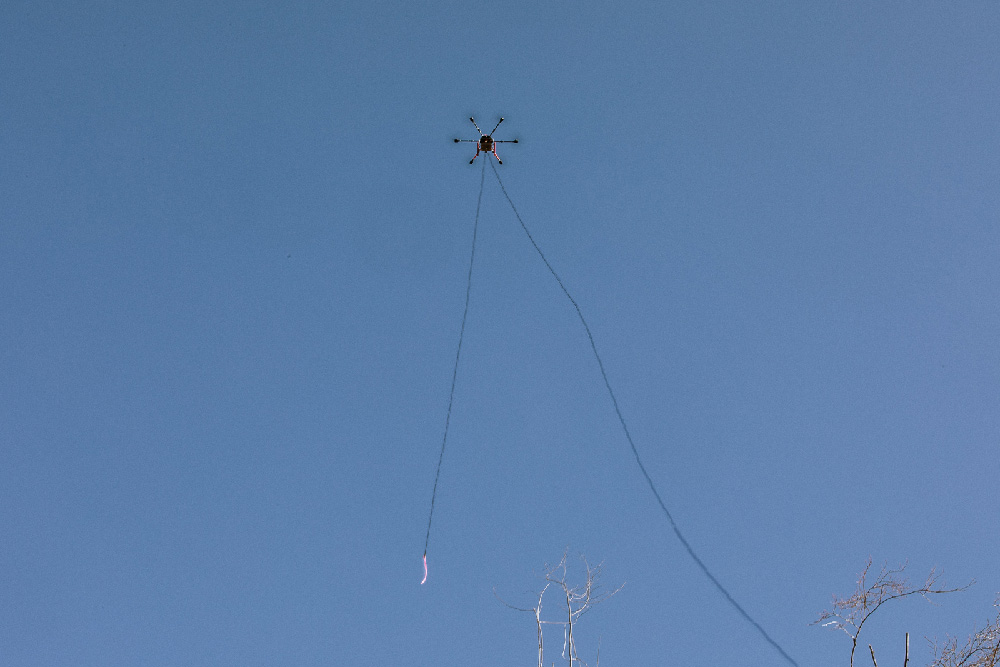

While it is still done on foot in many cases, large drones are becoming an increasingly popular, safer alternative. Rather than losing a day’s work or more having several people carry and disperse the cable, a drone can carry it through the sky. It travels from the tower to the “tailhold” the cable will attach to across from the slope the logs are on.

A tailhold can be a strong tree or stump that will hold steady under the weight of the cable and the logs it carries. If there isn’t anything strong enough, a heavy vehicle can also be used.

Further Reading: To learn more about how drones are now being used to put skylines into place, check out our article and video, High Power Drones Are A Safety Game-Changer in Tower Logging.

Once the synthetic line connects the tower and tailhold, a stronger cable is then led through a spool, followed by the thick, heavy skyline that will be used in the next step. (Depending on who you ask, a spool can also be referred to as a pulley, sheave or block).

Moving Trees to the Sorting Yard

With the skyline cable in place, a motorized “carriage” can be placed on the cable to carry the logs up the skyline.

How do the logs get attached to the cable? Loggers called “choker setters” attach the logs to a choker (or babbitt), which is a separate cable that hangs from the carriage. It secures the logs with an interlocking mechanism called a bell and knob. (The bell-shaped side is like a keyhole, while the knob is like a key).

Ed Bryant, owner of ENB Logging, refers to choker setters as “the guys out in the brush who make things happen.” In addition to choker setter, they have also traditionally been called rigging slingers and rigging men.

This method is preferred over using on-the-ground equipment or people to move the trees on the dangerous slopes. And while it might be easier to drag logs on the ground, that would create deep ruts in the soils and send sediment into nearby waterways. In order to protect the water and the ecosystems that depend on it, loggers use the airborne option.

Further Reading: You can read more about how we protect waterways in forestry by checking out our video and article, How Foresters Restore Salmon Habitat in the Pacific Northwest.

Preparing the Logs for their Buyers

Once the logs have made their journey off the slope and into a flat area called a yard, it’s time to prepare them for transport. This could mean removing their bark and branches with an aptly-named debarker machine. The logs also might be cut to fit into the trucks they will be loaded onto.

The logs also will be sorted by size, quality and species in order to best determine which mill each group of logs will be delivered to. The highest quality logs will be used for products like flooring and lumber. Lesser quality logs can be processed into pulp, which is used in thousands of everyday products.

Further Reading: You can learn more about the products that are made from logs by reading our #ItStartsWithTrees series. Here’s a link to the first article in the series.

Leave a Comment