Dangerous tasks that took loggers hours or even days on steep mountainsides can now be safely done in minutes, thanks to powerful new drones.

GRAYS RIVER, Washington—When it’s your job to safely remove trees off mountainsides without disturbing the soils or nearby streams, you have to be a talented problem-solver.

Every forest presents new challenges, like a recent tower logging site here in the beautiful mountains of Grays River. Until recently, there would have only been one way to unwind cable down one steep mountain and up another to set up the skyline: on foot. But a new drone has turned a multi-day job like that into a 10-minute job.

How does Tower Logging Work?

First, a quick background on the steps it takes to remove trees from a steep slope here in the Pacific Northwest:

Step 1: Cut trees in an organized layout

A logging crew cuts the trees and places them on the ground in an organized layout, which will make them easier to move.

Step 2: Set up the tower and skyline

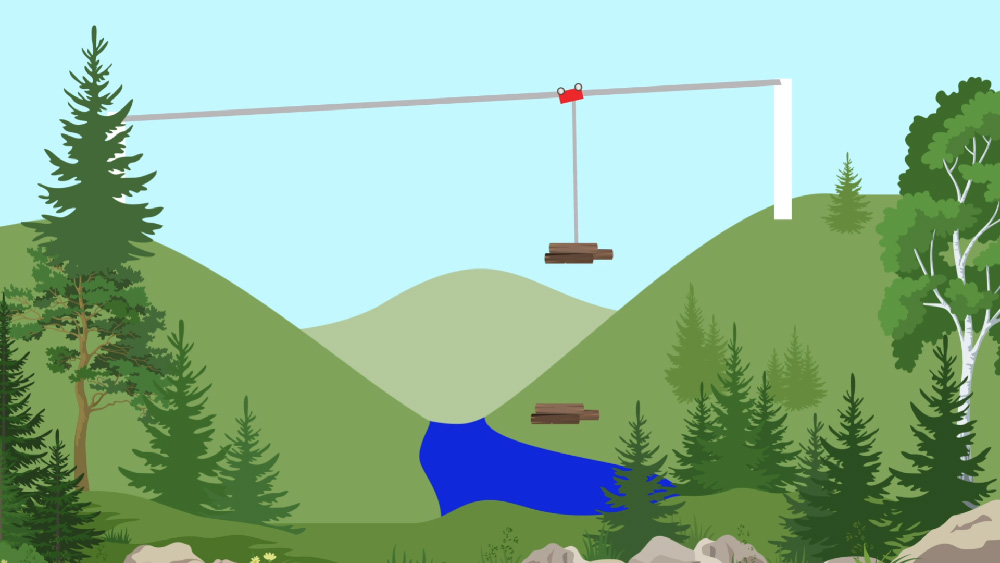

Loggers set up a tower connected to a cable system. The skyline cable has to stretch from the tower, across the slope the logs are on, to the top of a nearby slope. Setting this cable into place is the step where drones are involved, replacing the work of loggers who would have to spend hours if not days unwinding 100s of pounds of haywire down one slope and up the other to get the cable in place.

Step 3: Use skyline cable to move logs to sorting yard

A motorized “carriage” carries the logs up the skyline. Loggers called “choker setters” attach the logs to a chain that hangs from the carriage, securing them with an interlocking mechanism called a choker. Then the carriage lifts logs up into the air and moves them to a sorting area.

Did you know? Logs are lifted into the air to prevent them from dragging in the soil, which could lead to erosion and deposit sediment into nearby waterways. Airlifting also prevents damage to the log.

Step 4: Prepare logs for transport to the mills

Once the logs are in the sorting area, they are prepared for transport. This could include the removal of any remaining bark and branches, cutting the logs to fit the truck they will be on, and sorting them by species and size for the various needs of the mills they will be sent to.

For a more detailed description of this process, read our article, How Tower Logging Works.

How Drones are Making it Easier to Place a Skyline Cable

In order to lift bundles of 70-foot logs with a skyline cable, you first have to put a cable into place that stretches high above the ground. To do that, loggers start by unwinding 250-foot sections of synthetic cable (called haywire) as they walk from the tower at the top of the slope the logs are on, to the top of a nearby slope or peak.

This is usually done on foot. It can be exhausting and dangerous because of the terrain. The crew often has to go up and down the mountains multiple times to get more rigging until they finally reach their destination, often thousands of feet away from the starting point.

Stuck Between a River and Two Cliffs

On a recent logging job in Grays Harbor, featured in the video above, ENB Logging owner Ed Bryant knew his team would have to do the job differently. Between the slope they were logging and the slope their cable would stretch to, there was a deep river with high cliffs on both sides.

It would take a team of several people a long time to get the haywire in place. And they would have to get creative to get it across without losing it in the river. In the old days, they might have attached the cable to an arrow and shot it across with a bow. Or they might have dropped it over one cliff and fished it out from the top of the other cliff with a fishing pole.

But the cliffs were a safety hazard, the terrain was rough, and they would waste valuable time. Ed wasn’t going to put his team through that. It was time to call in a drone.

“It’s a good tool. If we didn’t have that option, we would’ve taken a few more days to get across,” Ed said as the drone pilot arrived.

An Unusual Drone to the Rescue

Thankfully for Ed, he’s not the first to run into this kind of challenge. Mark Standley of Banks, Oregon, spent most of his life logging. He saw many hours waste away placing haywire on dangerous terrain. Then he got into the business of creating drones to solve the problem.

Pacific UAV offers custom-made “workhorse” drones that can lift heavy weights, release items and even spout fire! While not all logging companies own the high-end drones, those that do own them can be hired to fly them for their colleagues.

Ed called C&C Logging Company. Soon, their drone pilot, Operations Manager Rex Pitullo, made his way up the mountain to help.

Rex attached the haywire to his Hector T drone using a servo attachment that releases by remote. Meanwhile, one of Ed’s team members drove to the peak of the next mountain. He then walked into the forest to find a strong tree to serve as the “tailhold” that the cable would connect to. Then he communicated with Rex by radio, guiding him to drop the cable nearby with his drone.

Using a Spotter to Guide the Drone

As the drone took off, haywire followed after it, quickly unwinding itself from a large container. Ed’s team stood alongside Rex, holding up binoculars to try to find their spotter on the ground across the slope. The man waved his orange coat, trying to help the team spot him. But with tall trees all around him, he was barely visible.

“A little to the right, a little to the right, now come in straight ahead,” the spotter said over the radio.

“I’m not the one flying the drone,” Rex said as he positioned the drone above the spotter. “My spotter guides me where I need to be.”

When the spotter could clearly see the drone within close proximity to the tailhold, Rex used the remote to command the drone to drop the haywire, trying to avoid any tree branches that could tangle with it. After a few minutes of searching, the spotter found it and secured it into place.

Rex says that’s just one of the many ways the drone is impacting forestry work. His drone can assist in firefighting, deliver bags of seedlings to planting sites, bring tools to workers whose equipment breaks down in remote areas, and countless other uses.

Celebrating a Milestone in Safety and Efficiency

With the cable line quickly in place, Ed’s team got back to work. The team pulled a stronger cable through a pulley, or spool. Finally, they pulled a strong cable through. This one would be able to support the weight of the motorized carriage and its loads of logs.

They were days ahead of where they would have been, thanks to a single drone flight.

“I’ve been doing this for 47 years, and this is pretty new to me,” marveled ENB logger Dave Johnson.

To Rayonier’s Timber Production Forester Scott Grigg, who works with our logging contractors to come up with the safest possible harvest plans, it’s an exciting step forward in forestry safety.

“The dollar value (of using a drone) is a big deal, but the safety factor is insurmountable,” he says. “It shows just how much this industry has embraced technology to keep people safe.”

Leave a Comment